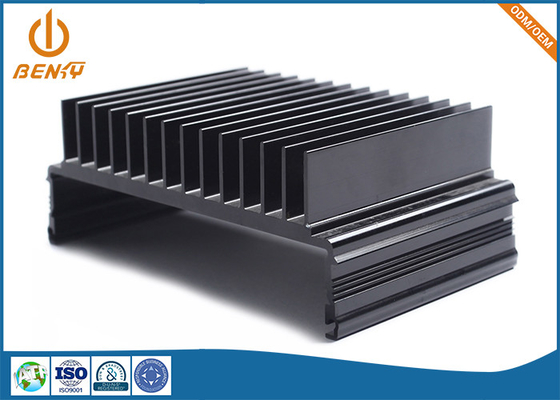

OEM Aluminum Extrusion Processing Heat Sink For Photovoltaic Inverter

6063 Series Anodized Aluminum Extrusion Gold Apple Extruded Aluminum Heat Sink For Photovoltaic Inverter

Customized surface finishes are welcome

1) High corrosion resistance, high weather resistance and good wear resistance.

2) Excellent material for smooth and subtle edges, elegant appearance.

3) Thickness: above 0.8mm

4) Usage: millions of different use.

5) Alloy and temper: 6061,6063, 6060,6005 or other alloys, temper can be T4/T5/T6 etc.

Chemical Composition Of Aluminium Profile

|

Alloy |

Si |

Mg |

Fe |

Cu |

Mn |

Zn |

Cr |

Ti |

Impurity |

Ai |

|

|

Unit |

Total |

||||||||||

|

6063 |

0.2-0.6 |

0.45-0.9 |

<0.35 |

<0.1 |

<0.1 |

<0.1 |

<0.1 |

<0.1 |

<0.05 |

<0.15 |

Surplus |

|

6061 |

0.4-0.8 |

0.8-1.2 |

<0.7 |

<0.15-0.4 |

<0.15 |

<0.25 |

0.04- 0.35 |

<0.15 |

<0.05 |

<0.15 |

Surplus |

|

6060 |

0-0.6 |

0.35-0.6 |

0.1-0.3 |

≤0.1 |

≤0.1 |

≤0.15 |

≤0.05 |

<0.1 |

<0.05 |

<0.15 |

Surplus |

|

6005 |

0.6-0.9 |

0.4-0.6 |

0.35 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.05 |

<0.15 |

Surplus |

Surface Treatment

|

Class |

Min-average film thickness |

Min-Part film thickness |

|

AA10 |

10 |

8 |

|

AA15 |

15 |

12 |

|

AA20 |

20 |

16 |

|

AA25 |

25 |

20 |

![]()