3C industry, lighting decoration, electrical appliances, auto parts, furniture parts, electric tool, medical equipment, intelligent automation equipment, other metal casting parts

Get a Quote

Thanks for your interesting with our Zinc die casting PARTS!!!

We are professional in Zinc casting, such as zinc die casting, zinc gravity casting, zinc sand casting.

Zinc casting has below advantages:

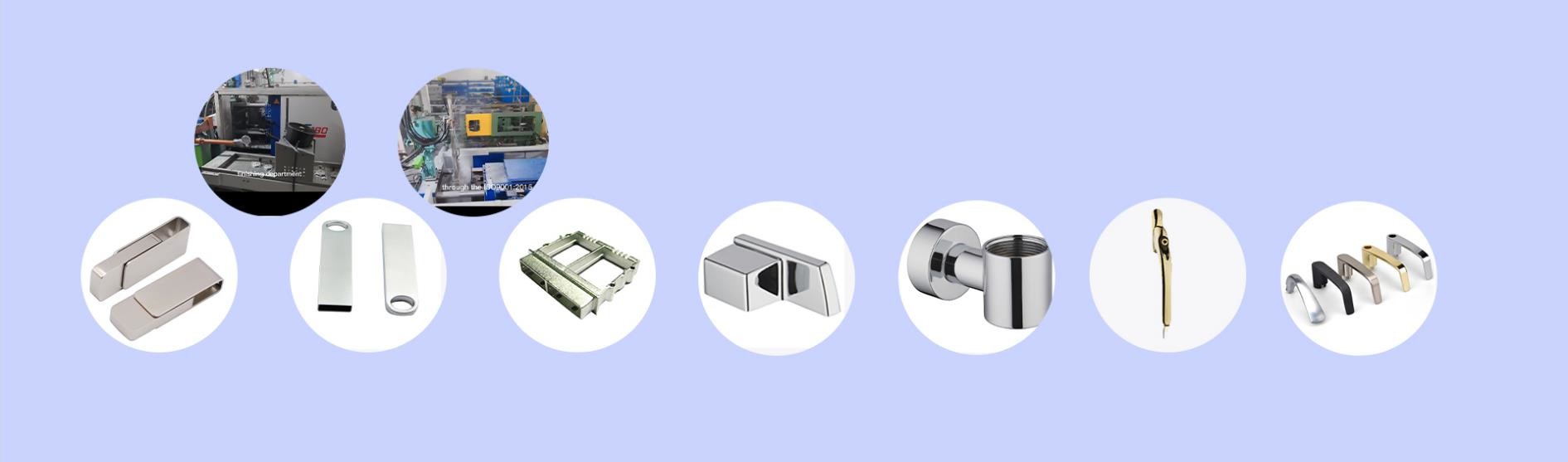

As zinc casting parts designer, manufacturer, supplier in Shenzhen China, our zinc part factory have more than 30 years experience with zinc casting, sells the zinc casting products all over the world. Our zinc casting parts include zinc casting gear housing, zinc casting case, zinc casting pipe fittings, zinc casting connector housing, zinc casting toy part, zinc casting adaptors, zinc casting box, zinc casting light parts, zinc casting auto parts, zinc casting pump parts, zinc casting valve body, zinc casting electronic component, zinc cast fishing reels etc.

ZINC DIE CASTING PART PRODUCTION

-Our zinc casting foundry is specialized in manufacturing zinc casting parts together with full capacity of CNC machining for castings.

-Design and manufacture capability for zinc casting tooling and products

-Design capability for aluminum injection die casting parts

- Common material: Zamac alloy 3, zamak alloy 5, zamac alloy 7, etc.

-excellent finish technique for zinc casting partt include: alodine, anodizing, powder coating, polishing, Nickel plate, chromate plating, zinc plating, gold finish, e-coating, wet painting, passivation and etc.

Here below are zinc casting material we often use:

| Zamac #2 | Zamak #3 | Zamac #5 | Zamak #7 | ZA-8 | ZA-12 | ZA-27 | |

| Aluminum (Al) | 3.9-4.3 | 3.9-4.3 | 3.9-4.3 | 3.9-4.3 | 8.2-8.8 | 10.8-11.5 | 25.5-28.0 |

| Magnesium (Mg) | .025-.05 | .03-.06 | .03-.06 | .01-.02 | .02-.03 | .02-.03 | .012-.02 |

| Copper (Cu) | 2.7-3.3 | 0.1 | .7-1.1 | 0.1 | .9-1.3 | .5-1.2 | 2.0-2.5 |

| Iron (Fe) | 0.035 | 0.035 | 0.035 | 0.075 | 0.035 | 0.05 | 0.07 |

| Lead (Pb) | 0.004 | 0.004 | 0.004 | 0.002 | 0.005 | 0.005 | 0.005 |

| Cadmium (Cd) | 0.003 | 0.003 | 0.003 | 0.002 | 0.005 | 0.005 | 0.005 |

| Tin (Sn) | 0.0015 | 0.0015 | 0.0015 | 0.001 | 0.002 | 0.002 | 0.002 |

| Nickel (Ni) | - | - | - | .005-.020 | - | - | - |

| Zinc (Zn) | Bal. | Bal. | Bal. | Bal. | Bal. | Bal. | Bal. |

Quality: Perform ISO9001, process approach and loop control

Delivery

-The delivery time we advise is reasonable and precision.

-Extra qty will be produced in our warehouse for stock each time, so anytime you need the delivery is possible.

-If production meets delay, we will inform to you in the first time. And we take the most efficiency plan to solve the problem.

Any of your comments and queries will be highly appreciated. Thanks!

Product Description

FAQ

1. Q: Which kind of product can you do?

A: Mould manufacturing & die-casting for aluminum, zinc, copper, magnesium alloy parts.

2. Q: Which kind information need for die casting mould making quotation?

A: 1) Sample photo with size or 2D/3D design

2) Cavity quantity

3) Runner type, cold or hot

4) Mould steel type H13, SKD-61, 8407, 3Cr2W8V, 4Cr5MoSiV, W400 and so on.

5) Die-casting machine parameter or plate size(tie rod distance)

3. Q: I have no 3D drawing, how should I start the new project?

A: You can supply us a sample, we will help to finish the 3D drawing design.

4. Q: Why choose us?

A: High quality, professional service, factory price, and timely delivery.

Our services cover all industries and reach all parts of the world.We can make all kinds of products for you according to your design.