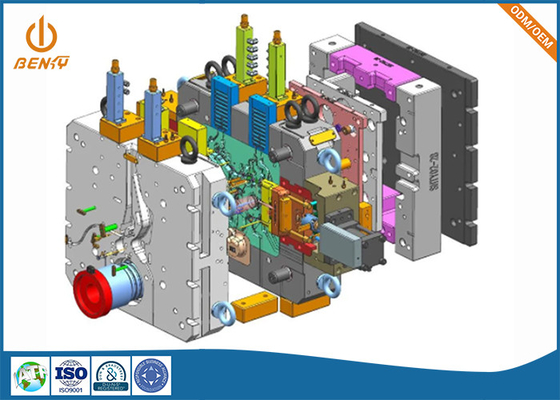

Polishing Sandblasting Die Casting Aluminum Auto Parts Customized Design

OEM Aluminium Die-Casting Auto Parts or Machinery Parts

Our plant occupies a floor area of 30,000 m2, and we have 500 well-trained employees and 40 research staff. Our annual capacity of die cast is 30,000 tons and our annual capacity of molds has exceeded 300 sets. We have more than 40 die-casting machines ranging from 280T to 4000T, and the largest casting weight can be 50KG. We also have more than 200 CNC machining centers, and have introduced the large-scale gantry machining center and large-scale precise five-axis machining center.

Aluminium made Auto part (motor part), ADC12 or A380 material. size from 5mm to 10,00mm. weight from 3g to 50kg. deferent desifn by buyer or combine developed with us. and diecasting tooling also available. all products from die-cast to surface treatment all finished in our factory.

| Machine | Die casting machine 88 ton/280 ton/400 ton/500 ton/800 ton/1250 ton/1650ton/2000ton/4000ton | ||||||||

| Material | Aluminum alloy ADC10 . ADC12 . A 360 . A380 .zinc alloy | ||||||||

| Process | Drawing & Samples→Mould making→ Die casting → Deburring → | ||||||||

| Drilling and threading → CNC Machining → Polishing → Surface treatment | |||||||||

| → Assembly → Quality inspection → Packing →Shipping | |||||||||

| Surface treatment | Polishing, Sandblasting, Painting, Powder coating, Galvanizing, Chrome plating,Spray coating, | ||||||||

| Application | Led light housing & Led Heatsink | ||||||||

| Auto & motocyle & bicycle parts | |||||||||

| Furniture accessories | |||||||||

| Power tool housing | |||||||||

| Pump housing | |||||||||

| Mechanical parts | |||||||||

| Diecasting kitchen utensils | |||||||||

| Drawing Format | Auto CAD,CAD, PDF,3D, SLDPRT | ||||||||

| ISO Cetificate | ISO9001-2015, Rohs | ||||||||

| Payment term | T/T, L/C, Western union | ||||||||

| QC system | 100% inspection before package or one by one | ||||||||

| Lead time | 10~25working days according on quantity | ||||||||

| Monthly capacity | 50,000pcs | ||||||||

| Our advantage | More than 30 years of experience in die casting field. | ||||||||

| With talented and experienced engineers | |||||||||

Q1:Are you manufacturer?

A:Of course we are.We Have our own factory.So we accept customization.Our company located in Shenzhen city where is the most large mold base.

Q2:What's your lead time?

A:Mold manufacturing time:It depends on the product size and structure, usually the mould making lead time is 25 to 35days,die casting production time;according to the steps and complexity of product processing,and the quantity of the order

Q3:How to control the quality?

A:We have QC department,three-coordinate measuring machine,projector,high gauge etc in mass production stage,we will have the professional QC and die casting and plastic injestion engineers to control the product quality,test 10pcs each hour.

Q4:What Surface finishing can your provide?

A:We can provide shot blasting,polishing,painting,powder coating,anodizing,electroplating,Chrome Plating(Matt/Bright),Nickle plating,Zinc Plating,mirror polishing,trivalent chromate passivation,e-coating,etc.

Q5:Do you provide prototyping service?

A:We can help you with your protoyping needs and expecting the high volume production.

Q6:If I send you the 3D file,why do you still need 2D drawing?

A:The 3D file is very useful,but there are some ohter requirement not indicated like the toler-ance and the sueface treatment apply in the part.This is why the 2D file is needed

Q7:What other qusetions can I get the fast quotation?

A:The annual quantity,materials selected,application or function of the parts,project delivery schedule,net weight(if you don't it,you must give us the 3D file),destination port.

Q8:What materials Saige offer?

AlSaige offer Aluminum And Zine Alloy for die casting.For example ADC12,ADC6,A380,AlSi12Cu1(Fe),AlSi9Cu3,etc.