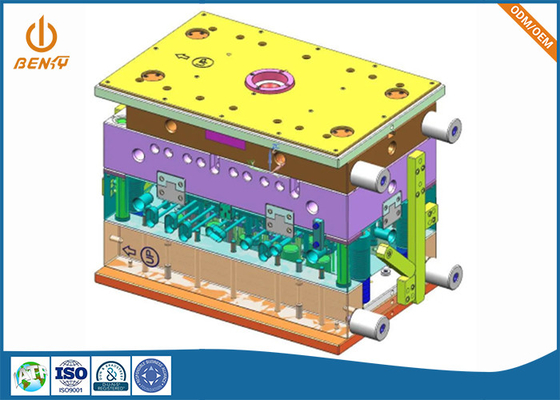

High Precision Plastic Injection Moulds Custom LKM HASCO DME Base

Customized High Precision Plastic Mould Products Maker Injection Mold Manufacturer Mouldings For Factory

Shenzhen Benky Industrial Co., Ltd mold specializes in high quality Plastic Injection Molding with more than 100 employees. It is founded in 1990. At the beginning, we produced the plastic injection molds and the household plastic parts for domestic companies, or some international trade companies. Now we are concentrated in international market. After more than 16 years'development in this industry, we know the international plastic injection molding standards well, such as: HASCO, DME, MISUMI, LKM. Until now, we have produced more than 5000 sets of molds and have been molding millions of medical plastic parts for Sony, Toshiba, Volvo, Gree, Midea! Our products reach to the range of electronic products, automotive products, home appliances,medical parts and so on.

|

Mould Structure

|

Injection mould

|

|

Shaping Mode

|

Plastic injection mould

|

|

Mould material

|

P20,P20HH,718,718H,718HH,738,NAK60,NAK80,S136,2738,2344,2083,2316,H11,H13,SKD61

|

|

Product Material

|

PP, PC, PA6, PA66, PPS, PC/ABS, PS, POM, PE, PU, PVC, ABS, PMMA, etc

|

|

OEM/ODM

|

Acceptable

|

|

Certification

|

ISO9001:2015

|

|

Design software

|

3D Pro/E,UG,Solidworks;2D AutoCAD,CATIA

|

|

Mould life

|

200000-1000000 shots

|

|

Mould base

|

HASCO,DME,CHINA LKM STANDARD,PUNCH,YUDO

|

|

Mold making

|

Based on drawing or samples

|

|

System of Runner

|

Cold or hot runner

|

|

Surface Treatment

|

Spraying, chrome plating, screen printing, leather grain

|

![]()

FAQ: