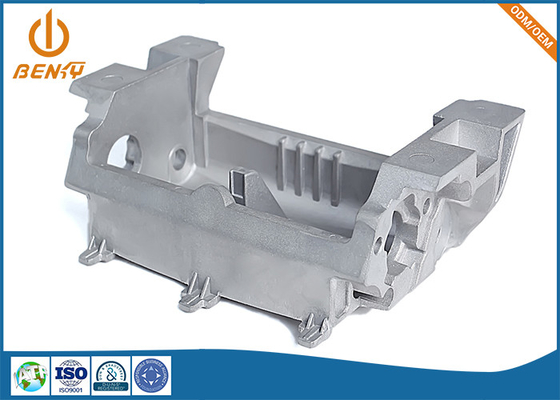

Ra0.8 Ra3.2 Die Casting Auto Parts Spraying Electrophoresis Anodizing

Aluminium Die Casting Machinery Parts OEM Aluminium Die Casting For New Energy Enclosure

We can process aluminium, magnesium, zinc alloy, steel and stainless steel products. Surface treatment includes spraying, electroplating, electrophoresis and anodizing.The company has foreign trade department, engineering department, quality department, assembly and packaging department, production department (mould making, die casting, CNC, post-processing), engineering and technical personnel 40, quality management personnel 30. Production and processing products mainly include high-strength and corrosion-resistant products such as naval display shell, porthole, drinking water supply pipe connectors, water meter shell periphery, communication and Internet electronic terminal equipment heat dissipation shell, lamp, microphone shell, sports equipment metal accessories, especially good at processing large-scale die-casting products with complex structures.The company's sales market is mainly in China's Pearl River Delta, Hong Kong, Macao and Taiwan, Northwest Europe, East Asia, North America and other regions.

|

Name

|

Factory Custom Aluminum Alloy Die Casting Auto Car Parts,New Energy Enclosure

|

|

Material

|

ADC12, A380, AlSi9Cu, ADC10

|

|

Dimension

|

Mini 80*80 mm, Max800*800 mm

|

|

Technology

|

High Preressure Die Casting, CNC, CMM Measure, Painting, X-Ray Detection

|

|

Processing

|

1, Sign Drawing (General clients provide the drawing or samples)

2, Opening the Mold 3, Die Casting ( Aluminium or Aluminium Alloy) 4, Precision Machining (Burring, Lathe, Milling, etc) 5, Surface treatment: Polishing, Electroplating, Sandblasting, Anodizing 6, Inspection and Packing |

|

Application

|

Automobile 42%, Furniture 21%, Industry 18%, Lighting 15%, Other 4%

|

![]()

![]()

Q1. Are you a factory or trade company?

A: We are a factory with over 30 years in die casting and CNC machining. We service customers aluminum die casting ,mold design, die casting, machining and Product assembly.

Q2. Where is your factory?

A: Our factory locates in Shenzhen china, 45 minutes drive to Shenzhen airport, 1.5hs drive to Hongkong

Q3:Available for customized design drawings?

A:2D(PDF/DXF/DWG fomat file)3D(IGS/STEP format file)

Q4:How to know the production process ?

A:We will send digital pictures and videos show you the production process

Q5:Do you provide samples ?

A:Yes , we could offer the sample for customer to check quality and specification.

Q6:Will my drawing be safe after you get it?

A:Yes , we can sign the NDA before you send the drawing.

Q7:What is lead Time for order?

A:In General , For sample , it is take about 10 days , and for mass production, it Is take 30 days.

Q8:What`s the MOQ ?

A:5piece sample , we accept sample order for customer to check quality ad specification.100pcs/batch.

Q9. Payment terms

A: Mold costs: 40% prepay upon order confirmation, balance after sample approval Mass production: 30-50% prepay, balance upon B/L available.

Thank you for your watching!!!